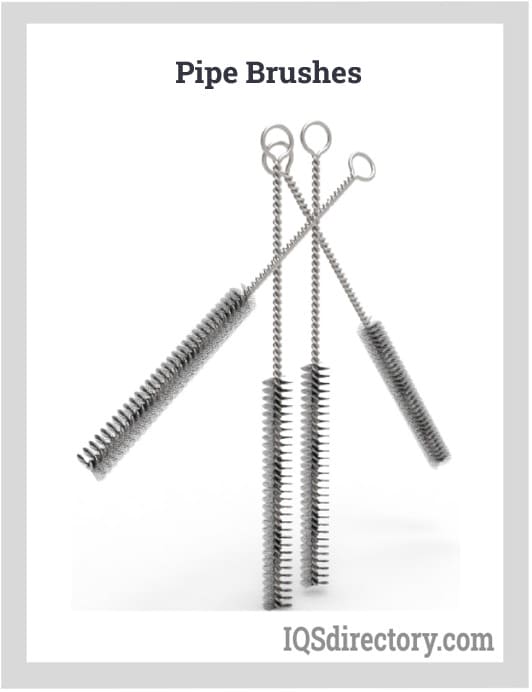

Pipe brushes have been used for centuries in various forms, with modern pipe brushes first introduced in the mid-19th century. Pipes and tubes are used in various industries, such as plumbing, manufacturing, and automotive maintenance. Over time, pipes can become clogged with dirt, debris, and other contaminants, decreasing functionality and potential health hazards. Pipe brushes are crucial in removing these blockages, restoring the proper flow of fluids, and maintaining the system’s hygiene. In addition, pipe brushes can help prevent future blockages and damage to the pipes, ultimately saving time and money in repairs and replacements. Read More…

Gordon Brush® is an ISO 9001:2015 certified manufacturer of standard & specialty brushes for the commercial, aerospace, military, medical & electronics industries.

Spiral Brushes manufactures industrial brushes, custom brushes, power brushes, wire brushes, conveyor cleaning brushes, steel brushes, stainless steel brushes, brass brushes, nylon brushes, abrasive nylon brushes, and natural fiber brushes.

The Industrial Brush Co. is a provider of brushes. Since 1946, we have been committed to providing high quality brushes and customer service for a variety of industrial applications and marketplaces.

Justman Brush is an ISO 9001:2015 Registered Manufacturer centrally located in the United States. We manufacture brushes for a large variety of industrial applications for our customers in the industrial, aerospace, military, laboratory & scientific, medical and food service industries. With over 91 years of manufacturing experience, we have the American Quality, competitive pricing and short...

Precision Brush Company is an industry leader that has the technology, expertise and experience to satisfy all of your brush requirements.

Braun Brush is committed to manufacturing quality brushes using a variety of methods. We offer convenient purchasing of the most extensive brush line available & a unique design-your-own brush service on the web.

For over 30 years, Tanis has been a leading brush manufacturer. Tanis has put innovation to work in everything we do, using the latest technology, materials, manufacturing advancements and engineering expertise.

More Pipe Brush Manufacturers

Differences Among Pipe Brushes

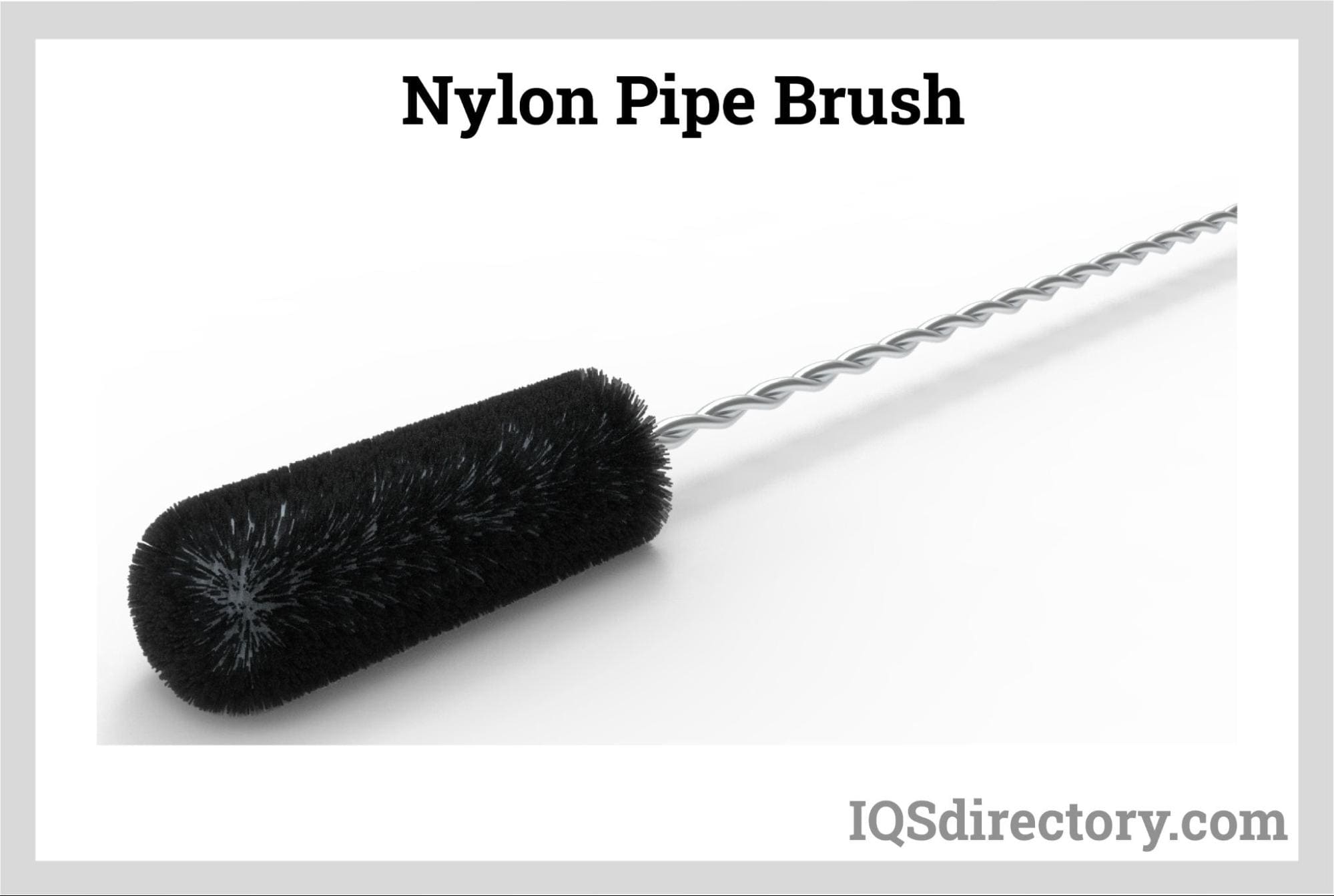

Pipe brushes come in various sizes, shapes, and materials. The size and shape of the brush depend on the diameter and length of the pipe being cleaned. The bristle type can also vary, from soft to hard bristles, depending on the level of cleaning required and the type of pipe being cleaned. Pipe brushes can be made from various materials, such as stainless steel, nylon, brass, and horsehair.

Some materials may be more appropriate for certain types of pipes or materials, while others may be more durable or resistant to damage. For example, stainless steel pipe brushes are commonly used in industrial cleaning, as they are highly durable and corrosion-resistant. Nylon brushes are suitable for use on delicate surfaces, such as chrome or porcelain, as they are less abrasive than other materials. Brass brushes are used for more heavy-duty cleaning, as they are stronger and more abrasive than other materials. Finally, horsehair brushes are used for sensitive cleaning applications, such as in food processing plants, as they are gentle and non-abrasive.

Generally, the material used to make a pipe brush is selected based on the level of cleaning required, the type of pipe or material being cleaned, and the desired level of abrasion or gentleness. While some materials may be more effective for certain types of pipes or materials, the choice of material ultimately depends on the user's specific cleaning needs and preferences.

Items That Damage Pipe Brushes

To maintain the lifespan of pipe brushes, it is important to avoid exposing them to harsh chemicals, high temperatures, and incorrect storage. Harsh chemicals can corrode the bristles or handle, while high temperatures can damage them. Improper storage, such as storing pipe brushes in damp areas, can lead to mold growth and damage to the bristles.

Tips for Extending the Life of Pipe Brushes

Proper cleaning, storage, and maintenance can help extend the lifespan of pipe brushes. Regular cleaning of pipe brushes can help prevent the buildup of dirt and contaminants, while proper storage can prevent damage from moisture and mold growth. Regular maintenance, such as trimming the bristles or replacing damaged handles, can also help extend their lifespan.

Limitations to the Usage of Pipe Brushes

Pipe brushes have limitations in size and shape, making them unsuitable for cleaning large or irregularly shaped pipes. Pipe brushes can also pose safety risks, especially when used incorrectly, such as damaging the pipe or causing injury to the user. Some materials may not be suitable for certain types of pipes or materials that could be damaged by the bristles.

Firstly, brittle or fragile materials, such as ceramic pipes or thin-walled plastic pipes, may be easily damaged by the bristles of a pipe brush. In such cases, alternative cleaning methods, such as air pressure or chemical cleaning, may be more appropriate.

Secondly, some pipe materials may be sensitive to abrasion or chemical reactions, such as copper or brass pipes. In these cases, it is important to use a pipe brush made from a material that is less abrasive or corrosive, such as nylon or horsehair. Thirdly, pipes with irregular shapes or bends, such as elbows or U-bends, may be difficult to clean with a traditional straight pipe brush. In these cases, special brushes, such as twisted wire brushes or flexible cleaning cables, may be more effective.

Finally, very large pipes or pipes with significant blockages may require specialized cleaning equipment, such as high-pressure water jets or mechanical snakes, as traditional pipe brushes may not be able to remove the blockages effectively.

Benefits of Pipe Brushes

Pipe brushes offer several benefits, such as effective cleaning, versatility, and cost-effectiveness. They are effective in removing dirt, debris, and blockages from pipes and tubes. They are relatively inexpensive and can last a long time with proper care.

Applications of Pipe Brushes

Pipe brushes can also be used in various applications. In general, pipe brushes are used in any industry or application where pipes or equipment need to be cleaned or maintained. Here are some examples:

Plumbing: Pipe brushes are commonly used in plumbing for cleaning drains, pipes, and fittings. They are often used to remove blockages, debris, or buildup from pipes, and to prepare surfaces for soldering or welding.

Industrial Cleaning: In industrial settings, pipe brushes are used for cleaning equipment, machinery, and industrial pipes. They are often used to remove rust, paint, scale, and other contaminants from metal surfaces, and to clean hard-to-reach areas.

Automotive Maintenance: Pipe brushes are commonly used in automotive maintenance for cleaning engine parts, brake components, and other areas where debris or buildup can accumulate. They are also used for cleaning carburetors, fuel injectors, and other automotive components.

Laboratory and Scientific Research: In laboratory and scientific research, pipe brushes are used for cleaning glassware and other laboratory equipment. They are often used to remove stubborn residues or contaminants from the surfaces of test tubes, flasks, and other laboratory glassware.

Food Processing: Pipe brushes are used in the food processing industry for cleaning and sanitizing pipes and equipment used in food production. They are often used to remove debris and contaminants from pipes, tanks, and other surfaces that come into contact with food products.

HVAC Maintenance: Pipe brushes are used in HVAC maintenance for cleaning air ducts, coils, and other components. They are often used to remove dust, dirt, and debris from air conditioning units, heat exchangers, and other HVAC components.

Choosing the Right Pipe Brush Supplier

To ensure the most beneficial outcome when purchasing pipe brushes from a pipe brush supplier, it is important to compare several pipe brush companies using our directory of pipe brush suppliers. Each pipe brush supplier has a business profile page highlighting their areas of experience and capabilities, along with a business profile page to directly communicate with the supplier for more information or request a quote. Review each pipe brush business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple pipe brush companies with the same form.

Brooms

Brooms Brushes

Brushes Static Eliminator

Static Eliminator Sweepers

Sweepers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services